- Your cart is empty

- Continue Shopping

What Is LOSP Timber? Uses, Treatment Process, and Applications

Table of contents

- What does LOSP stand for in timber treatment?

- How the LOSP treatment process works

- What does LOSP timber look like?

- What is LOSP timber used for?

- Where LOSP timber should not be used

- Is LOSP timber suitable for outdoor use?

- LOSP timber vs H3 treated pine

- Compliance considerations and treatment classes

- Can LOSP timber be painted or stained?

- Frequently asked questions

- Final word

LOSP timber turns up on a lot of jobs. Window frames. Weatherboards. Cladding. Fascia. It looks good, cuts clean, and paints well.

Yet it is also one of the most misunderstood treated timber products on Australian sites.

The questions are always the same.

Is it structural? Can it go outside? Is it the same as H3? Why does it cost more?

This guide answers those questions plainly. By the end of this blog, you will have a clear idea on how LOSP timber actually works, where it performs well, and where it causes problems if used incorrectly.

What does LOSP stand for in timber treatment?

LOSP stands for Light Organic Solvent Preservative.

The solvent-based system is the whole reason LOSP behaves differently to standard treated pine.

Instead of water-based preservatives being forced into the timber, LOSP uses a light solvent to carry fungicides and insecticides deep into the wood fibres. The solvent then evaporates. What’s left is protection. Not moisture.

This is the key point most people miss.

LOSP timber is treated without saturating the timber with water. That single fact explains almost everything about how it looks, how it performs, and where it should be used.

How the LOSP treatment process works

The LOSP treatment process is designed for precision, not brute force.

Here’s the simplified version:

- Dry timber is placed in a sealed treatment cylinder

- Air is removed under vacuum

- The LOSP preservative solution is introduced

- Vacuum and pressure cycles drive preservatives into the timber

- The solvent flashes off and evaporates

- The timber comes out dry and dimensionally stable

No swelling. No heavy moisture load. No extended re-drying period.

This is why LOSP timber can be machined before treatment and still come out straight. And why it’s used for joinery and appearance-grade applications.

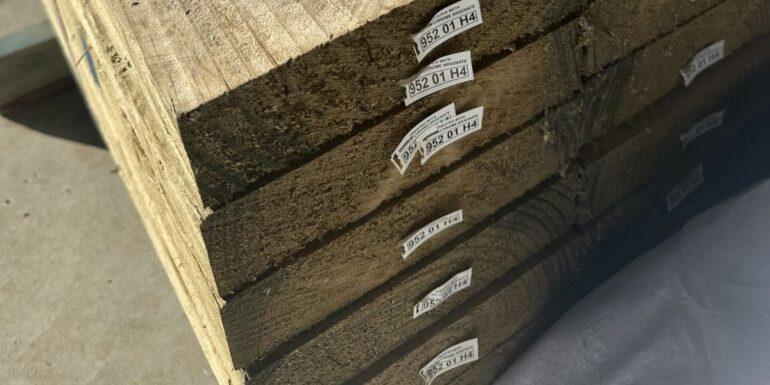

What does LOSP timber look like?

LOSP timber has a clean, finished appearance straight off the pack.

Typically:

- Smooth surface

- Sharp edges retained

- No surface salts or crystal build-up

Unlike water-treated pine, there’s no raised grain or roughness. It stays flat and true.

This is the main reason LOSP timber is specified where appearance matters. Paint finishes sit better, stains penetrate evenly, and gaps stay tight.

On paper, many treated timbers meet the same durability class. In practice, they don’t behave the same at all.

What is LOSP timber used for?

LOSP timber is used where appearance, accuracy, and stability are critical.

Common LOSP timber uses include:

- Window frames and sills

- Door frames and jambs

- External cladding above ground (protected applications)

- Fascia boards and barge boards

- Pergola posts above ground

- Weatherboards

Where LOSP timber should not be used

This is the biggest mistake seen on site.

LOSP timber is not designed for:

- Ground contact

- High moisture exposure

- Structural framing exposed to weather

- Decking or landscaping

- Fence posts or sleepers

If the timber is likely to stay wet, LOSP is the wrong product.

LOSP preservatives protect against insects and decay only when the timber can dry. They are not designed for permanent moisture exposure.

Is LOSP timber suitable for outdoor use?

Yes. And no.

LOSP timber can be used outdoors when:

- It is above ground

- It is well ventilated

- It is protected by paint or cladding systems

- Water is not trapped against it

LOSP timber should not be used outdoors where:

- It is exposed to constant rain splash

- Water can pond or soak into end grain

- There is soil contact

- It forms part of a deck or structural outdoor system

On drawings, this can look fine. On site, it often isn’t. This is where judgement matters.

LOSP timber vs H3 treated pine

This comparison causes endless confusion.

H3 treated pine:

- Water-based treatment

- Designed for above-ground outdoor exposure

- Good for decks, pergolas, external framing

- Rougher finish

- More movement after treatment

LOSP treated timber:

- Solvent-based treatment

- Designed for appearance-grade and precision work

- Excellent dimensional stability

- Limited moisture tolerance

- Not structural by default

Here’s the catch.

H3 is about durability. LOSP is about finish.

They solve different problems. This distinction matters more than people think.

Compliance considerations and treatment classes

In Australia, timber treatment must align with AS/NZS 1604 and exposure classifications.

LOSP timber is typically treated to:

- H2 (interior, termite protection)

- H3 (above-ground, limited weather exposure)

But not all LOSP timber is H3-rated. This is another common trap.

Always check:

- Treatment hazard level

- Intended exposure zone

- Manufacturer certification

- Whether cut ends need resealing

Can LOSP timber be painted or stained?

Yes. This is one of its strengths.

LOSP timber:

- Accepts paint extremely well

- Works with most stains and clear finishes

- Requires standard priming systems

- Benefits from proper end-grain sealing

One warning.

Some LOSP treatments leave solvent residues initially. Paint systems should follow manufacturer guidance, especially for early coating.

Rush it, and adhesion suffers.

Frequently asked questions

What is LOSP treated timber used for?

Primarily for appearance-grade applications such as window frames, door joinery, fascia, cladding, and trim where stability and finish quality matter.

Is LOSP timber suitable for outdoor use?

Only in above-ground, well-drained, well-coated applications. It is not suitable for ground contact or constant moisture exposure.

What is the difference between LOSP and H3 treated pine?

H3 treated pine is water-based and designed for outdoor structural use. LOSP is solvent-based and designed for precision, appearance, and stability.

Can LOSP timber be painted or stained?

Yes. It paints and stains very well when correct coating systems and preparation are used.

Final word

LOSP timber is not a shortcut. And it’s not a compromise product.

Used correctly, it delivers cleaner finishes, tighter tolerances, and fewer headaches. Used in the wrong place, it fails early and expensively.

That’s the reality seen time and again.

Understanding where LOSP timber belongs, and where it doesn’t, is what separates clean builds from problem jobs.

Timber Central helps builders get that right from the start. Correctly treated LOSP timber, supplied for the right job, with advice that reflects how timber actually performs on site.