- Your cart is empty

- Continue Shopping

Common Mistakes to Avoid When Working with LVL Engineered Wood

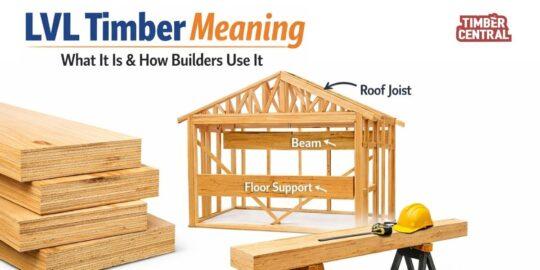

Laminated Veneer Lumber, or LVL, is strong, consistent, and widely used across all kinds of structural work in Australia. It’s become a popular choice for beams, joists, lintels, and flooring because of its load-bearing strength and reliability.

But it’s also not your average bit of timber.

It’s engineered to perform in specific ways. If you cut corners or skip the details, you might end up with twisted beams, delays on-site, or repairs down the line.

The good news? Most of these issues are avoidable.

Here are some common mistakes people make with LVL timber and how to avoid them.

1. Treating LVL Like It’s Just Regular Pine

On the outside, LVL might look like standard timber. But it’s not. It’s engineered to take bigger loads and span longer distances. That also means it needs a bit more care.

Leave it out in the rain, and you’ll be dealing with swelling or warping. LVL can soak up water fast. So always keep it dry, stacked flat, and off the ground.

If it gets wet, it might not bounce back the way pine sometimes can. That’s time and money down the drain.

2. Cutting Without Reading the Specs

You’re on-site. You need to trim a beam. No big deal, right? Actually, it can be.

Not all LVL products are the same. Some can be trimmed at certain points. Others can’t. Some are treated. Others aren’t. If you cut without checking the manufacturer’s guide, you risk damaging the strength of the whole piece.

Spend five minutes reading the instructions. Or just give your supplier a quick ring if you’re not sure.

3. Installing It the Wrong Way Around

LVL gets its strength from the direction of the grain. Install it sideways or flip it the wrong way, and that strength is gone.

It might hold for now, but give it a few months or years, and things can start to sag or shift. Always make sure you’ve got the orientation right. It’s one of those simple things that can make or break a job.

4. Not Sealing Cut Edges

Every time you cut LVL, you open up the timber to moisture. That raw edge can soak up water and weaken the beam over time.

It doesn’t take long to seal the ends. A quick coat with the right sealer helps keep it protected. It’s a small job that saves you big trouble later.

5. Storing It Like It’s Scrap

LVL isn’t something you can just dump in a pile. If it’s sitting uneven or exposed to rain, it can warp before you even get to use it.

Keep it flat. Raise it off the ground. Throw a tarp over it if you’re expecting bad weather. Think of it like you would plasterboard; you wouldn’t leave that out in the open either.

6. Not Asking for Certification

There’s plenty of LVL on the market. Not all of it meets Australian Standards.

Using uncertified LVL might save you a few bucks upfront, but it could cause problems later. Especially if you’re working under building codes or in bushfire zones. Always ask your supplier for the paperwork. It’s not overkill; it’s just good practice.

One Bad Mistake Can Cost You Later

LVL timber is a solid product when it’s used the right way. But when it’s not, problems can sneak up on you.

Warped beams, structural issues, or call-backs after handover are all things you don’t want. A bit of care now saves you headaches later.

So if you’re using LVL in construction, treat it with the respect it deserves. Store it right. Cut it properly. Install it how it’s meant to go. And if anything seems off, ask the question before you go ahead.

This isn’t just about the timber. It’s about doing the job right.

Not Sure Where to Start?

If you’re unsure about using LVL engineered wood, don’t guess. Call your supplier. Check the specs. Or speak with your site supervisor or inspector.

The best time to ask is before the job goes wrong, not after.

Need a Hand? We’ve Got You Covered.

At Timber Central, we supply quality LVL timber that meets Australian Standards, and we back it with the support tradies actually need. If you’ve got questions about the right product for your job or how to use it properly, just give us a call or drop by.

We’re here to make sure you get it right the first time.