- Your cart is empty

- Continue Shopping

Longevity of LVL: What Maintenance Is Required Over Time?

Short answer? Laminated Veneer Lumber (LVL) can last for decades, even up to 50 years or more, if it’s properly cared for. But like any building material, its longevity depends on how it’s treated after installation. Ignoring small maintenance steps can cut that lifespan short.

So, how much care does LVL really need, and what should you look out for?

What Makes LVL So Durable?

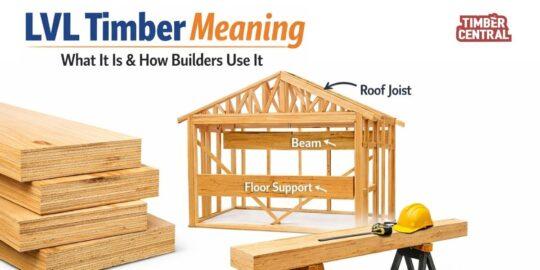

LVL is engineered to be tough. It’s made by bonding thin wood veneers together with strong adhesives. This creates a product that’s stronger and more stable than traditional solid timber.

The big advantage? LVL resists warping, shrinking, and twisting, even under pressure. That’s why it’s often used in beams, rafters, and structural framing.

But LVL is durable, not indestructible. It can still be affected by moisture, pests, and poor handling over time.

Does LVL Need Regular Maintenance?

Yes, but not as much as you might think. LVL doesn’t need constant upkeep like untreated timber, but it does benefit from regular checks.

Here’s what to focus on:

- Moisture control: LVL performs best when kept dry. If exposed to prolonged moisture, it can swell or lose strength. Ensure proper sealing and ventilation in all installations.

- Protective coatings: For outdoor or semi-exposed areas, a protective sealant or paint can help prevent moisture penetration.

- Pest prevention: LVL is less attractive to termites than raw timber, but still inspect regularly, especially in high-risk areas.

- Load checks: Over time, structural loads can shift. It’s smart to have a builder or engineer inspect beams and supports every few years.

Think of LVL maintenance like car servicing; small check-ups prevent big problems later.

How Long Does LVL Actually Last?

In well-protected conditions, LVL can last anywhere from 30 to 50 years or more. Indoors, it can last even longer since it’s not exposed to the elements.

Poor installation or neglect, however, can drastically reduce that lifespan. For example, if moisture gets trapped during construction, decay can start quietly inside the material before any visible damage appears.

So yes, LVL is long-lasting, but only when it’s respected as the engineered product it is.

How Can You Extend LVL’s Life?

There are a few simple but powerful steps to keep LVL performing for decades:

- Store it properly before installation. Keep it off the ground and covered to prevent moisture exposure.

- Seal the ends after cutting. This reduces the chance of water soaking into exposed veneers.

- Avoid direct ground contact. LVL should always be elevated or properly protected from soil and water.

- Check your ventilation. Poor airflow around LVL beams in subfloors or roofs can trap moisture and shorten lifespan.

Doing these things doesn’t take long, but the payoff is huge.

What Happens If You Skip Maintenance?

Cutting corners might save a few dollars now, but it’ll cost more later. Moisture damage can lead to swelling, delamination, or rot. Replacing structural LVL beams is no small job, and the repair costs can add up fast.

In Australia’s mix of hot summers and humid conditions, prevention is always cheaper than repair.

Is LVL a Good Long-Term Investment?

Absolutely. LVL remains one of the smartest choices for modern construction because of its strength, consistency, and predictable performance. When cared for correctly, it offers long-term stability and reliability that traditional timber often can’t match.

That’s why builders across Australia continue to choose LVL for homes, offices, and industrial structures. It delivers confidence, not just in how it performs today, but in how it holds up for decades to come.

Final Thoughts

LVL is built to last, but maintenance plays a key role in keeping it that way. A little attention every few years can help you avoid major headaches later.

If you’re planning a new project or replacing old structural timber, choose LVL from a trusted supplier.

Timber Central provides high-quality LVL that meets Australian standards and delivers proven durability for all types of builds. Reach out today to discuss your project, and let’s make sure your LVL stands the test of time.

FAQs

1. Can LVL be used outdoors?

Yes, but it needs to be sealed and protected from direct exposure to rain and ground moisture.

2. Does LVL attract termites?

It’s less likely than regular timber, but termite protection is still recommended in risk areas.

3. Can damaged LVL be repaired?

Minor surface issues can be fixed, but structural damage usually requires replacement. Always consult a professional.

4. How often should LVL be checked?

Every two to three years, or sooner if it’s in a damp or exposed location.