- Your cart is empty

- Continue Shopping

LVL Timber Meaning: What It Is and How Builders Use It

LVL timber is one of those materials that everyone in construction has dealt with, yet not everyone explains the same way. It appears on engineering drawings. It gets specified for beams and lintels. It turns up on site wrapped in plastic, perfectly straight. Still, the meaning behind LVL timber is often half-understood.

That gap causes problems. Wrong assumptions, incorrect substitutions, and sometimes expensive fixes that could have been avoided.

This guide explains LVL timber meaning in plain terms. What it is, how it’s made, and why it shows up so often in modern Australian construction.

What LVL Really Stands For, and Why That Matters

LVL stands for Laminated Veneer Lumber. That name is not decorative. Each word points to how the product behaves structurally.

Laminated means the member is built up from multiple layers rather than cut from a single piece of timber. Veneer refers to thin sheets of wood, peeled from logs, not sawn boards. Lumber tells you the end result is a structural product, not a finishing material.

Put together, LVL is an engineered structural timber made by bonding thin veneers together so the grain runs in the same direction. Strength follows the grain. LVL is designed so nearly all of it works in the direction the load is applied.

Thus, LVL is not “better pine.” It is a different category of timber altogether.

What Is LVL Timber Made From?

Most LVL used in Australia is manufactured from softwood species, commonly radiata pine. The raw material itself is not unusual. What matters is how it is processed and controlled.

Logs are peeled into thin veneers, typically only a few millimetres thick. Those veneers are dried to precise moisture levels and assessed before being bonded together with structural adhesives. Defects are spread across layers rather than concentrated in one location, which dramatically improves reliability.

This is where LVL separates itself from solid timber. Natural timber always carries variability. Knots, grain deviation, density changes. LVL is designed to manage those variables instead of hoping they don’t line up in the wrong place.

That predictability is the real value. Not appearance. Not novelty. Predictability.

How LVL Timber Is Manufactured

The manufacturing process behind LVL is tightly controlled because it has to be. Structural performance depends on it.

Veneers are laid up so the grain direction remains parallel throughout the billet. Adhesives are applied consistently. Pressure and heat are used to create a single, stable structural member. Large billets are then cut down into beams, joists, or lintels of specific sizes and grades.

What comes out the other end is uniform, straight and consistent from one length to the next.

Strength and Performance: What Actually Matters on Site

LVL timber is designed to carry load in a predictable way. That predictability is more important than raw strength numbers.

LVL typically offers high strength relative to its size, consistent stiffness, and minimal movement once installed. Shrinkage is lower than solid timber. Twisting and bowing are reduced. Long spans behave the way calculations say they should.

This is the main reason LVL shows up in structural applications. Not because it is fashionable, but because it behaves.

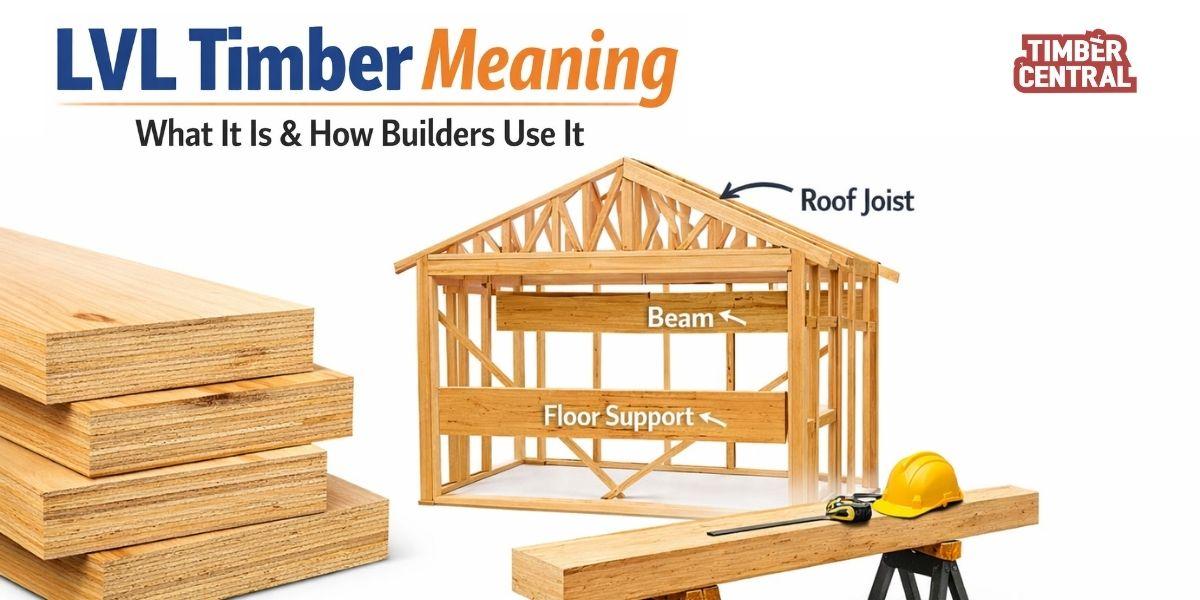

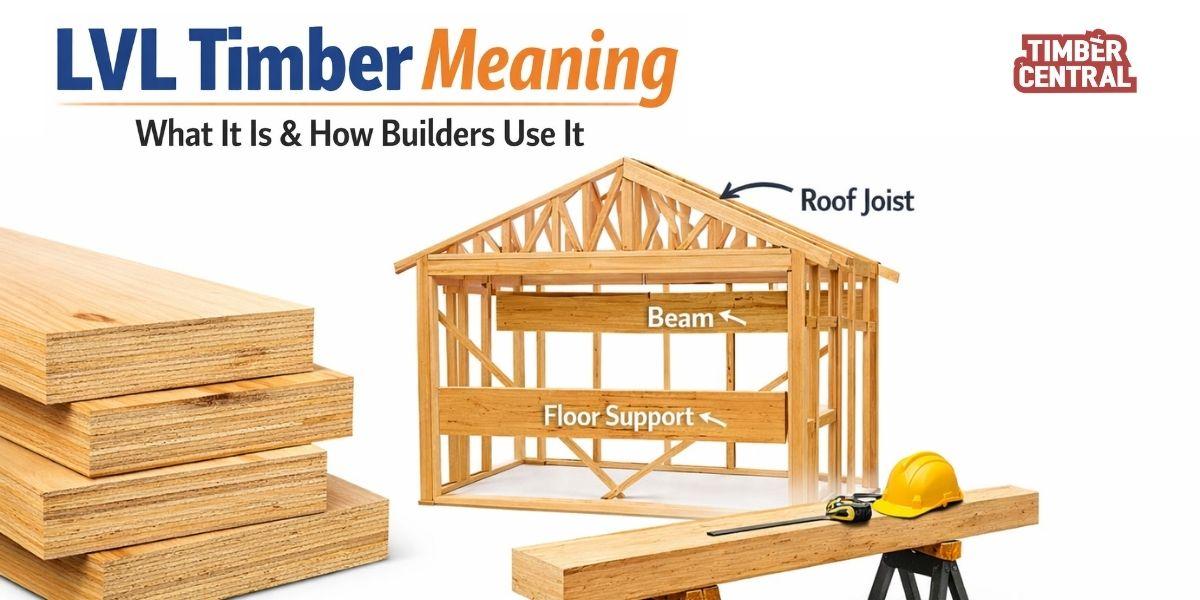

Where LVL Is Typically Used in Construction

LVL timber uses are almost always structural. Floor joists carrying long spans. Roof members where deflection matters. Beams and lintels supporting wide openings. Portal frames and garage headers where loads concentrate.

In residential builds, LVL often replaces large solid timber sections that are difficult to source or unreliable over time. In light commercial work, it allows designers to achieve open layouts without excessive depth or bulk.

This is not about preference. It’s about meeting structural requirements within the constraints of modern design.

LVL Beams Explained

LVL beams are simply LVL sections sized and graded to resist bending loads. The principle is straightforward. Align the grain. Spread the defects. Control the material.

Because the veneers all run in the same direction, the beam works efficiently along its span. Weak points don’t stack on top of each other. Stiffness stays consistent from one end to the other.

This is why LVL beams are trusted in applications where deflection limits are tight. They behave the same way on site as they do in calculations.

LVL vs Solid Timber: The Real Comparison

Comparing LVL to solid timber is unavoidable. It’s also often oversimplified.

Solid timber has advantages. It’s familiar. Easy to work with. In short spans, it can be economical and effective. When sourced well, it performs perfectly adequately.

The limitation is variability. No two pieces are the same. Knots, grain run-out, and moisture movement all influence performance. Large sections are harder to source, and movement over time is harder to predict.

LVL addresses those issues by design. It offers consistency, higher allowable stresses, and reduced long-term movement. The trade-off is that it must be detailed and handled correctly.

One is not universally better than the other. But they are not interchangeable. Treating them as such is where problems start.

LVL vs MGP Timber: A Common Misunderstanding

Machine-graded pine (MGP) and LVL are often confused because both carry strength ratings. That’s where the similarity ends.

MGP timber is solid pine graded based on stiffness. It still contains natural defects and variability. LVL is manufactured to achieve uniform structural properties across the entire member.

Substituting one for the other without engineering approval is a mistake. A common one. And one that can derail compliance quickly.

LVL Structural Timber in the Australian Context

LVL structural timber in Australia is governed by the NCC, relevant Australian Standards, and manufacturer design guides. Engineer specifications sit on top of that framework.

Material selection is not optional. Instead, it is a compliance requirement. Any change to specified timber, whether from LVL to solid timber or the reverse, requires proper approval.

When LVL Is Typically Specified

LVL is usually selected when spans push beyond standard framing limits, when deflection control is critical, or when consistency across multiple members is required. Large openings, architectural layouts, and load concentrations all tend to point in this direction.

It sounds simple, but it isn’t.

LVL is not chosen because it looks good on paper. It’s chosen because it performs under regulation.

Clearing Up Common LVL Misconceptions

- LVL is not “just glued timber.” It is an engineered structural product with published design values.

- LVL is not automatically stronger than solid timber, but it is far more predictable.

- LVL cannot be treated like standard pine. Installation rules exist for a reason.

- LVL is not limited to commercial projects. It is used daily in residential construction.

Timber Central and Structural Timber Supply

Timber Central supplies LVL and structural timber to builders across Melbourne and Victoria, with a clear focus on compliance and practical application.

The role is straightforward. Supply the correct product, with the right documentation, aligned to Australian standards and project specifications. Nothing more. Nothing less.

Because structural timber mistakes don’t stay hidden.

FAQs

What is LVL timber?

LVL timber means Laminated Veneer Lumber. It is an engineered structural timber product made by bonding thin wood veneers together with the grain aligned for strength and consistency.

Is LVL stronger than solid timber?

Not always. LVL’s advantage lies in consistency and predictability, which allows engineers to rely on published design values with confidence.

Where is LVL commonly used in construction?

LVL is commonly used for beams, joists, lintels, rafters, and other load-bearing elements in residential and light commercial buildings.

Can LVL timber be used outdoors?

Only where the product is specified, treated, and detailed correctly. Most LVL is designed for internal or protected applications unless otherwise stated by the manufacturer.

Understanding the meaning of LVL timber isn’t about memorising terminology. It’s about knowing why it exists, where it performs best, and where assumptions usually cause trouble.

Get that right, and LVL does exactly what it’s designed to do. No surprises.