- Your cart is empty

- Continue Shopping

LVL’s Dimensional Stability: No Warping, No Worries

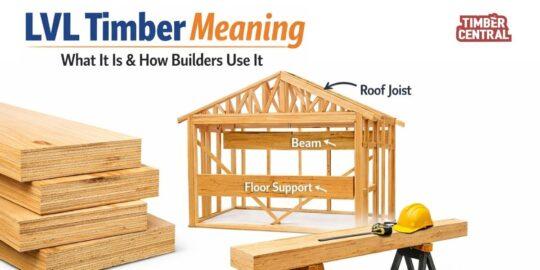

When building in Australia, the last thing needed is a beam that warps or twists on you. The clear answer is this: LVL (Laminated Veneer Lumber) offers superior dimensional stability; no warping, no surprises. Keep reading to see why that matters and how Timber Central delivers on that promise.

Why Does Dimensional Stability Even Matter?

You’ve probably seen timber beams bend, twist or crack over time. That leads to squeaky floors, gaps in walls, or doors that stop closing properly. In our climate, with hot summers, humid spells, and temperature swings, wood is under constant stress.

When timber moves unpredictably, costs pile up: extra fixes, wasted materials, delays. You don’t want your project undermined by wood that can’t keep its shape.

What Makes LVL So Stable?

Engineered by Design

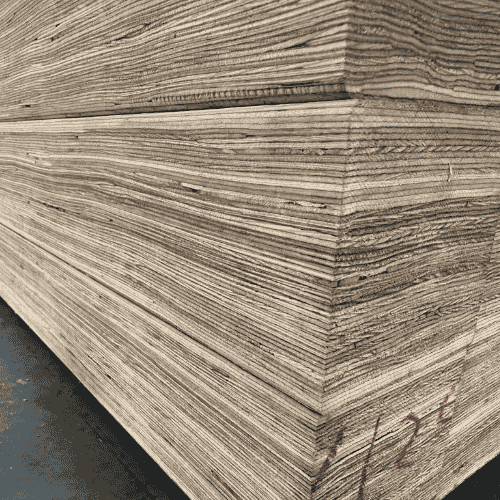

LVL is made by glueing together many thin veneers with grains aligned in the same direction. This process evens out the stress inside the wood. The result: a beam far less likely to warp, twist, or shrink compared to solid timber.

Controlled Moisture, Controlled Behaviour

In a factory, the moisture content is tightly controlled before assembling LVL. That means the timber won’t drastically expand or contract once it’s installed.

Spread Defects = Less Weakness

Any knot or grain irregularity is spread across many layers. That reduces its impact on the whole beam. In simple terms, a flaw in one layer is diluted by its neighbours.

Built to Stay Straight

Because of its structure, LVL holds shape over time, even under load. That means fewer surprises years down the line.

What Happens When You Don’t Use LVL?

Let’s go through what could (and often does) happen when you choose standard sawn timber instead:

- Warping or twisting, especially across wide spans.

- Shrinkage or expansion causing wall cracks or gaps.

- Failing joints, as movement stresses fasteners or connectors.

- Maintenance hassles, you’ll keep patching or replacing.

Those are real headaches, not just theory.

Why LVL Is a Smart Choice in Australia

- Climate resilience: Our weather is punishing on wood; LVL resists that.

- Long spans: LVL can handle longer unsupported distances without bending.

- Less waste: Fewer rejects and more consistent boards reduce waste.

- Reliability: Engineers and builders trust LVL because its performance is predictable.

How Timber Central Delivers on the Promise

Timber Central sources high-grade LVL that meets strict quality standards. The supply is backed by technical specs so that builders know what their timber will do, not just what it “might” do.

Whether for beams, roof joists or headers, LVL from Timber Central gives confidence, not just at handover, but years later.

If warping, twisting or shrinking have kept your projects awake at night, Timber Central is here to change that. Contact the team today and plan your next job with materials you can trust.

FAQ

Can LVL ever warp or move?

Under extreme conditions (water damage, severe misuse), any wood can shift. But LVL’s design makes it much more stable than traditional timber.

Does LVL cost more than solid timber?

Yes, initially. But when you factor in reduced maintenance, fewer defects and longer life, it is often more cost-effective over time.

Is LVL suitable for all parts of a house?

Yes. LVL is often used for beams, lintels, rafters, floor joists and more.

How should LVL be protected on site?

Keep it dry before installation, protect it from weather exposure, and avoid direct contact with wet ground. Proper installation is important to maintain stability.