- Your cart is empty

- Continue Shopping

How Kiln-Drying Enhances Structural Timber Performance on Site

Kiln-dried timber gives you a stable and dependable result on site. This matters when the goal is to keep your work straight, safe, and within budget. Many problems seen on Australian builds come back to one thing. Moisture. Kiln-drying helps control that from the start.

This blog explains why kiln-dried options like F17 KD hardwood and MGP10 are widely used across the country and why they often save time and stress during construction.

The Problem Many Builders Face

Every builder knows the frustration of timber that twists soon after framing. You set a stud today and it shifts out of line tomorrow. That leads to delays, waste, and callbacks.

This happens when the timber still carries too much moisture. Once it starts drying out on site, it changes shape. Walls bend. Floors squeak. Fixings loosen. It becomes a chain reaction that takes time and money to fix.

No one wants that.

How Kiln-Drying Helps Control Moisture

Kiln-drying brings the moisture content down in a controlled process. The timber is placed in a heated chamber where temperature and airflow stay steady. This gives the timber a steady feel that holds up well in real conditions. You get lengths that stay in shape even when the weather moves from hot to humid within a day.

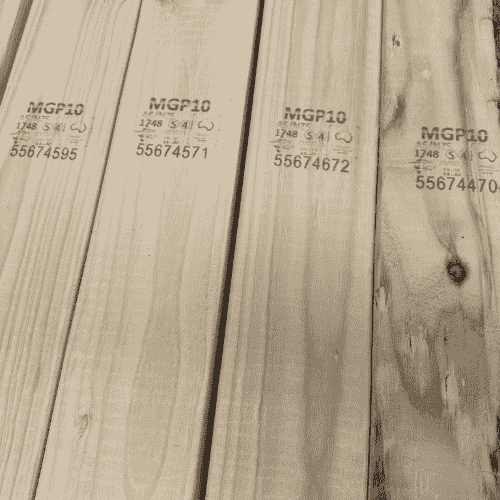

F17 KD hardwood and MGP10 are good examples. They are graded at stable moisture levels, so the performance you expect on site is the performance you get.

Better Handling During Installation

Fewer surprises

Kiln-dried timber is easier to work with. It stays straight, which means less time correcting pieces that bend or twist.

Reliable strength

The grading is more dependable because the moisture level is consistent. This helps when you need timber that meets structural demands without guesswork.

Cleaner fixing

Nails and screws hold better in timber that is dry enough. You avoid the splitting and tearing that can show up in wet timber.

Lighter weight

Reduced moisture means less weight. This makes lifting, cutting, and framing easier, especially in tight spaces or multi-storey jobs.

How Kiln-Dried Timber Supports Long-Term Stability

Movement after handover can lead to expensive corrections. Doors stick. Walls open up. Floors shift. These faults often come from timber that continued to dry after installation. Kiln-dried timber limits this movement. A stable product helps the structure hold its shape and reduces the risk of early repairs.

A simple question often guides the choice. Is it worth risking movement when a more stable option is available?

Where Kiln-Dried Structural Timber Fits Best

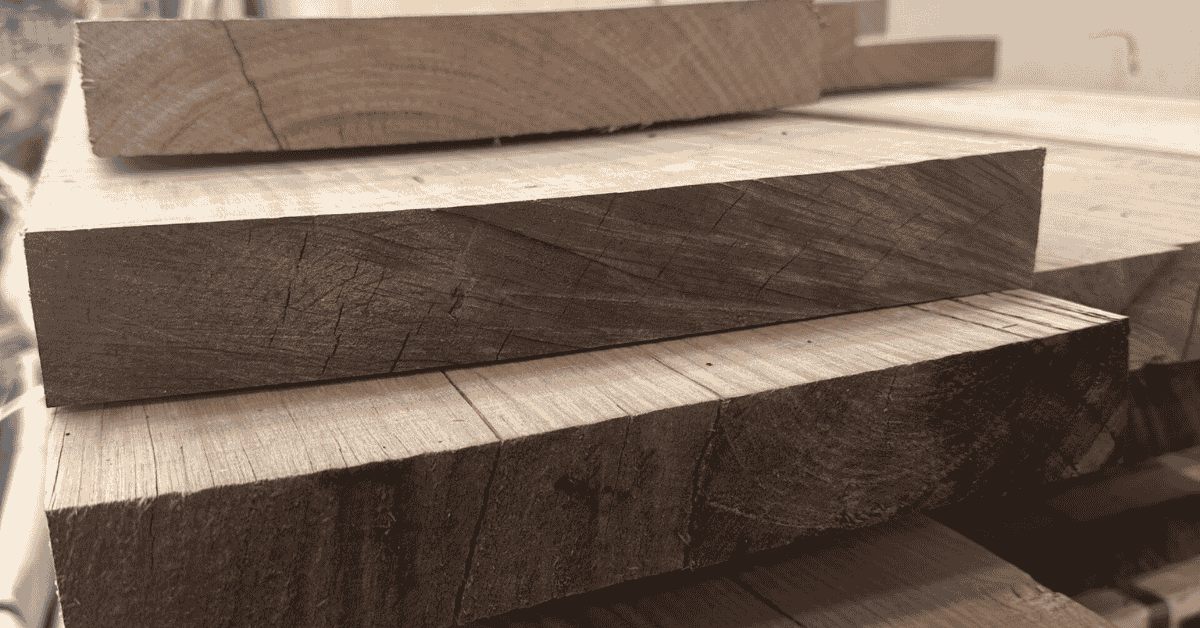

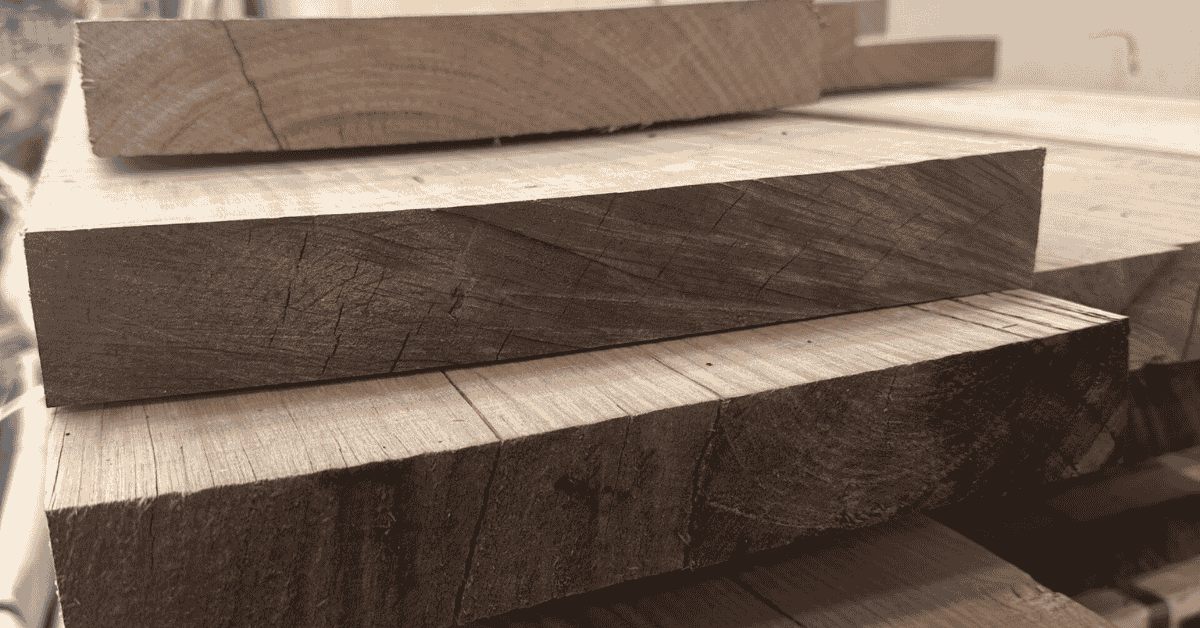

Kiln-dried F17 hardwood and MGP10 are used across many Australian projects. They suit residential and commercial framing, beams, and general structural work. The controlled drying gives each piece a uniform result, which is valued by carpenters and inspectors alike.

Final Advice

For builders who want consistent results and fewer site issues, kiln-dried timber is a practical and reliable choice. It cuts down on waste, reduces rework, and supports a stronger frame.

Timber Central supplies F17 KD hardwood and MGP10 for builders who want steady performance and fewer site issues. Choosing a stable product now may help you avoid costly fixes later.

FAQs

Does kiln-dried timber still shrink?

It may shrink slightly, but much less than unseasoned timber.

Is kiln-dried timber only for framing?

It can be used for many structural and internal applications depending on the grade.

Does kiln-dried timber need special storage?

It should be stored off the ground and covered to protect it from rain and direct sun.