- Your cart is empty

- Continue Shopping

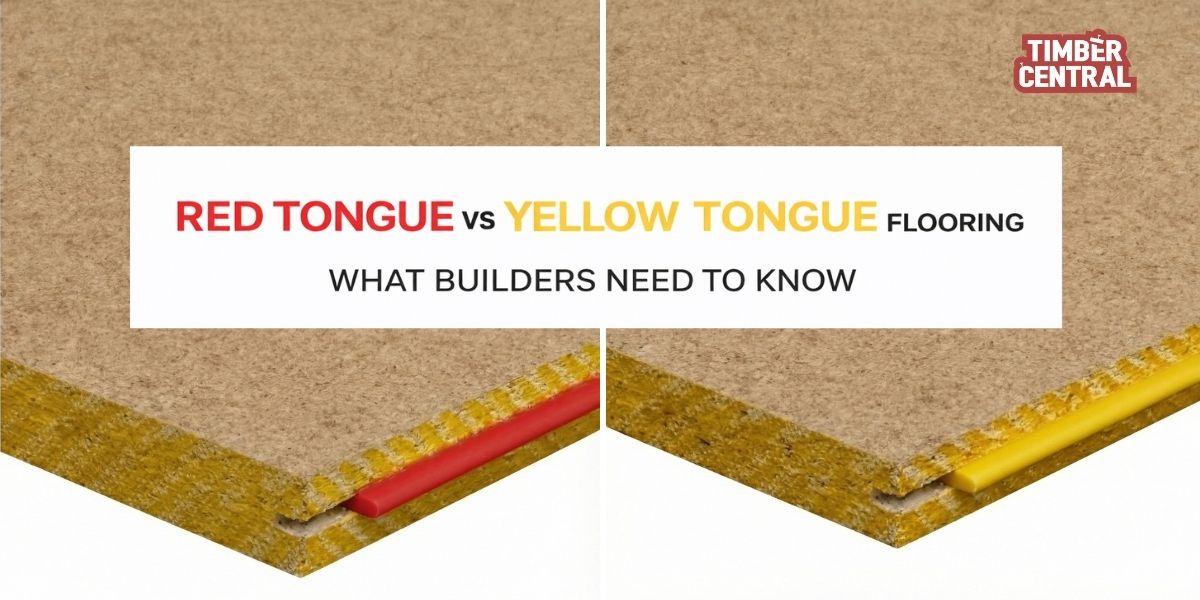

Red Tongue vs Yellow Tongue Flooring: What Builders Need to Know

Table of contents

- What Red Tongue and Yellow Tongue Flooring Actually Are

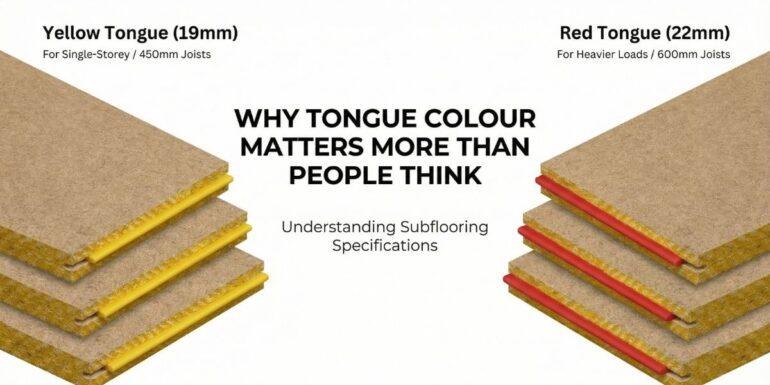

- Why Tongue Colour Matters More Than People Think

- Thickness Differences

- Moisture Resistance Levels Explained

- Typical Uses of Yellow Tongue Flooring

- Typical Uses of Red Tongue Flooring

- Red Tongue vs Yellow Tongue: Side-by-Side Comparison

- Compliance, Standards, and Product Selection

- Why Getting This Right Prevents Flooring Failures

- FAQs

- Final Takeaway for Builders

The red tongue vs yellow tongue question comes up on jobsites constantly. And for good reason.

At a glance, both products look similar. Tongue-and-groove particleboard. Structural flooring. Widely used across residential construction in Australia.

That’s where the similarity ends.

These boards are not interchangeable, and the difference is not just the colour of the tongue. Thickness, moisture resistance, exposure classification, and approved use all vary. Miss one of those details, and problems show up later. Usually after handover. Usually expensively.

This guide breaks down red tongue flooring vs yellow tongue in practical terms. What they are. Where each is typically used. And where builders most often get caught out.

What Red Tongue and Yellow Tongue Flooring Actually Are

Both red tongue and yellow tongue are structural particleboard flooring products manufactured to Australian Standards for use as load-bearing subfloors.

They are designed to:

- Span between joists

- Provide structural support

- Act as the base for finished floor coverings

But they are manufactured to different performance levels.

The tongue colour is not branding. It is a site identifier used across the industry to indicate the board’s moisture resistance classification and, in most cases, its thickness and structural rating.

Why Tongue Colour Matters More Than People Think

The coloured tongue tells builders, inspectors, and certifiers what level of moisture resistance the board has been manufactured to.

In broad terms:

- Yellow tongue flooring is moisture resistant particleboard designed for interior, protected applications

- Red tongue flooring is manufactured for higher moisture exposure risk and is commonly supplied in a thicker, heavier-duty profile

Here’s the key point.

Tongue colour correlates with performance expectations under Australian Standards.

Using the wrong board in the wrong environment does not just increase risk. It can place the build outside approved specifications.

This is where most people get caught out.

Thickness Differences

Yellow Tongue Flooring Thickness

Yellow tongue flooring is most commonly supplied at 19mm thickness, designed for standard residential floor loads where the structure is protected from ongoing moisture exposure.

It is not designed to compensate for prolonged wetting or site delays.

Red Tongue Flooring Thickness

Red tongue flooring is commonly supplied at 22mm thickness, offering:

- Greater stiffness

- Higher load capacity

- Improved resistance to movement when exposed to moisture

Thickness can vary by manufacturer and product line, but in practice, red tongue is heavier-duty flooring. That extra thickness is deliberate. It supports performance in more demanding environments.

Assuming both products are “basically the same” because they look similar is a mistake.

Moisture Resistance Levels Explained

Both products are described as moisture-resistant. That wording causes confusion.

Moisture-resistant does not mean waterproof. It means the board can tolerate a certain level of moisture exposure without excessive swelling, provided installation and protection requirements are followed.

- Yellow tongue has a lower swelling tolerance

- Red tongue has a higher swelling tolerance

That’s the difference.

In laboratory testing, red tongue boards demonstrate less thickness swelling after moisture exposure than yellow tongue boards. This directly affects:

- Joint integrity

- Flatness

- Long-term floor performance

Many builders assume internal floors never get wet. In theory, yes. In practice, sites don’t always cooperate.

Typical Uses of Yellow Tongue Flooring

Yellow tongue flooring uses are well established across Australian housing.

Typical applications include:

- Standard residential internal floors

- Upper-storey flooring

- Living areas, bedrooms, hallways

Typical Uses of Red Tongue Flooring

Red tongue flooring uses apply where moisture exposure risk is higher, either during construction or over the life of the building.

Common scenarios include:

- Enclosed subfloor spaces with limited ventilation

- Areas where moisture levels are harder to control

- Certain light commercial or mixed-use applications

Red Tongue vs Yellow Tongue: Side-by-Side Comparison

Here’s the comparison builders actually care about:

Thickness

Yellow tongue: Commonly 19mm

Red tongue: Commonly 22mm

Moisture Resistance

Yellow tongue: Moderate

Red tongue: Higher

Typical Exposure Classification

Yellow tongue: Internal, protected

Red tongue: Higher moisture risk environments

Tolerance to Construction Delays

Yellow tongue: Limited

Red tongue: Better, not unlimited

Although both are structural flooring, they behave differently on site.

Compliance, Standards, and Product Selection

Structural flooring selection in Australia is governed by:

- NCC requirements

- Australian Standards

- Engineering documentation for the project

Product choice is not discretionary. It must align with the approved design and exposure classification.

Timber Central supplies red tongue and yellow tongue flooring that meets Australian standards. Selection should always be confirmed against project documentation and regulatory guidance.

When conditions change on site, the specification needs to be reviewed. Not guessed.

Why Getting This Right Prevents Flooring Failures

Most flooring-related defects linked to moisture trace back to one decision. The wrong board in the wrong place.

- Swelling leads to uneven surfaces.

- Uneven surfaces telegraph through finished floors.

- Finished floors fail.

By then, rectification costs far exceed the price difference between products. This is not theory. It’s what shows up again and again across residential builds.

FAQs

What is the difference between red tongue and yellow tongue flooring?

The difference lies in moisture resistance, thickness, and intended exposure conditions. Red tongue is typically thicker and more moisture-resistant than yellow tongue.

Is red tongue more water-resistant than yellow tongue?

Yes. Red tongue has higher moisture resistance, but it is not waterproof and still requires protection during installation.

When should builders use red tongue flooring?

Red tongue is typically used where moisture exposure risk is higher, subject to engineering design and regulatory approval.

Is yellow tongue suitable for all indoor flooring applications?

No. Yellow tongue is suitable for internal, protected environments only. It is not intended for higher moisture exposure conditions.

Final Takeaway for Builders

Red tongue vs yellow tongue is not a preference question. It’s a performance and compliance decision.

- Thickness matters.

- Moisture resistance matters.

- Exposure conditions matter.

Get those aligned with the approved design, and the flooring does its job quietly. For decades. Get them wrong, and the problems arrive later. Always later.